1. Efficiency:

The double rotor pump has the characteristics of high efficiency. The two impellers can achieve higher flow and more stable output pressure, and lower energy consumption.

2. Stability:

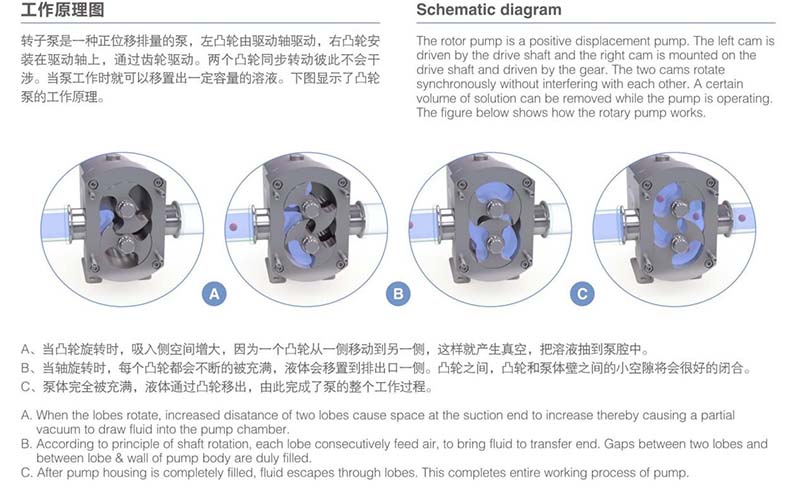

Due to its working characteristics, the sanitary lobe pump has two rotors for delivery, which can achieve stable delivery of the medium. The working principle diagram is as follows.

3. Economic efficiency:

Usually the price of a double rotor pump will be higher. Because of the design problem, the single rotorr pump has a smaller space and simpler design. The single rotor pump has a clear price advantage.

However, for the food and beverage industry, we recommend customers to use a double rotor pump, which has more stable delivery, protects the medium, has high efficiency, and high hygiene. The double rotor pump is a high-quality choice for the food and beverage industry.

4. Medium adaptability:

The twin-rotor pump performs well in medium adaptability, and is particularly suitable for industries with extremely high hygiene requirements such as food, beverages, and pharmaceuticals. Its rotor surface is smooth, made of food-grade stainless steel, and has a dead-angle design, which is easy to clean and disinfect thoroughly and can meet strict hygiene standards. At the same time, the twin-rotor pump has less shear force on the medium during the conveying process, which can effectively protect the integrity of materials containing particles or fragile materials such as meat and sauces. Due to the frictional contact between the stator and the rotor, the stator of the single-rotor pump is prone to wear when conveying high-viscosity or hard-particle-containing media, and more frequent replacement of parts is required. However, the single-rotor pump has certain advantages when conveying media containing fibrous substances. Its flexible stator can adapt to the winding of fibers and reduce the risk of blockage.

5. Industry application scenarios:

In the food and beverage industry, the twin-rotor pump has become the preferred equipment due to its stable conveying performance, high hygiene standards and low shear force characteristics. For example, in the process of conveying fruit juice concentrate, the twin-rotor pump can keep the pulp particles intact while ensuring stable conveying pressure and avoiding filling accuracy errors caused by pressure fluctuations. In the field of sewage treatment, the single-rotor pump is more suitable for conveying sewage containing sludge, fiber and solid particles due to its simple structure, wear resistance and anti-clogging characteristics. In addition, in the chemical industry, for media with large viscosity changes, the twin-rotor pump has stronger adaptability, while the single-rotor pump is more suitable for conveying media with relatively stable viscosity.

6. Maintenance and repair:

The maintenance of the twin-rotor pump is relatively complicated. Due to its precise internal structure, it is necessary to regularly check the meshing of the synchronous gears and the rotor clearance, and the maintenance cost is high. However, the maintenance cycle of the twin-rotor pump is longer, generally 12,000-15,000 hours, which reduces downtime. The maintenance of the single-rotor pump is relatively simple, the replacement operation of the stator and rotor is relatively simple, the maintenance cost is low, but the maintenance cycle is short, usually 6,000-8,000 hours. In terms of maintenance, twin-rotor pumps require professional technicians to operate, while single-rotor pumps have a lower maintenance threshold and can be completed by ordinary maintenance personnel.

Twin-rotor pumps (sanitary lobe pump) and single-rotor pumps each have their own advantages and disadvantages. Twin-rotor pumps are outstanding in efficiency, stability, hygiene and medium protection, and are suitable for industries with high transportation requirements; single-rotor pumps have advantages in cost, compact structure and anti-clogging ability, and are more suitable for cost-sensitive or complex medium transportation scenarios. Users should choose the most suitable pump type based on specific application requirements, medium characteristics and budget.

According to ASME BPE, EHEDG, FDA and 3A standard, DONJOY got certificates of PED-97/23/EC and MD-06/42/EC issued by TUV, ……