Final granule diameter after emulsifying and homogenizing: Final granule diameter (nM) depends on medium

High-efficiency dispersion, cut, refinement, smash,emulsification, mixing, homogenization, high purity solution

Max flow: 50m3/h

Max powe: 75KW

Temperature: -20℃~140℃

Media refinement: ≤ 60 GRIT (≈ 300μm) ≤ 60mesh (about300μm)

Material: 304 /316L, 1.431/1.4404, ASME BPE 316L, 1.4435 NB2 Fe≤0.5% Dual-phase steel 2205, Hastelloy alloy C276

Surface treatment: ≤ Ra0.8μm, ≤ Ra0.6μm, ≤ Ra0.4μm

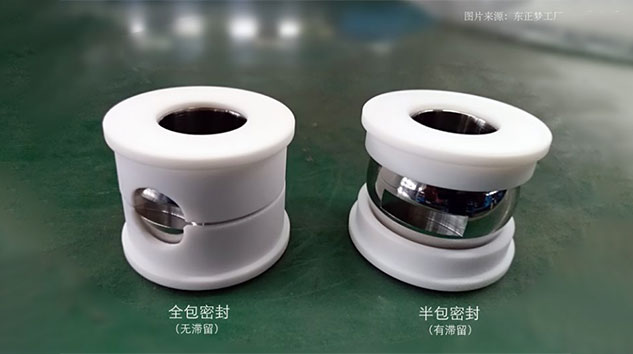

Mechanical seal: Single and double mechanical seal

Mechanical seal combination: See configuration table

Inlet/Outlet connection: Thread, clamp, flange, Aseptic flange

Certification: 3-A-02-12(N.O.1579); MD/06/42-EC (N.O.70521616101-00); FDA 177.2600; USP CLASS-II; EG/VO1935/2004

Technology Highlights:

1. Mobile Cart Design for Enhanced Flexibility

Industrial-grade casters with brakes for smooth multi-location operation

Quick-connect fittings enable rapid transitions between production stages

Modular components reduce maintenance costs by ~30% vs. fixed systems

2. Intelligent Homogenization Control

Digital display for real-time monitoring of particle size & pressure

Adjustable homogenizing pressure (0–1000 bar, model-dependent)

Thermal protection system prevents sample degradation

Industrial Applications:

✓ Pharmaceuticals: Liposomes, nanoemulsions, vaccine adjuvants

✓ Food & Beverage: Sauce emulsification, dairy homogenization, juice refinement

✓ Cosmetics: Nano-serums, stable lotions, pigment dispersion

✓ Chemicals: Nanomaterial synthesis, polymer processing, dye homogenization